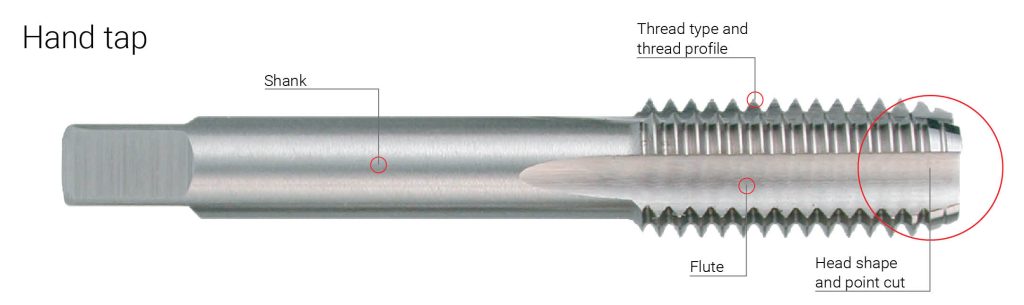

A machine tap, also known as a hand tap or simply a tap, is a cutting tool used to create internal threads in a hole or opening. It is commonly used in metalworking and machining processes to produce threaded holes that can accept screws, bolts, or other threaded fasteners. Here are some key aspects of machine taps:

Function:

Machine taps are designed to cut threads into pre-drilled or pre-machined holes. When rotated and gradually advanced into the hole, the tap removes material and creates helical grooves, resulting in internal threads that match the profile and pitch of the tap.

Types of Machine Taps:

Straight Flute Taps:

These taps have straight flutes running the entire length of the tap. Straight flute taps are commonly used for through-hole applications, where the tap can pass completely through the workpiece.

Spiral Flute Taps:

Spiral flute taps have flutes that twist around the tap body. The spiral design helps with chip evacuation, as it facilitates the removal of metal chips from the hole during tapping. Spiral flute taps are often used for blind-hole applications, where the tap does not pass through the entire workpiece.

Spiral Point Taps:

Also known as gun taps or through-hole taps, spiral point taps have a pointed end with a spiral flute design. The spiral point pushes the chips forward and out of the hole as the tap progresses. These taps are well-suited for through-hole applications, as they help facilitate chip removal.

Forming Taps:

Unlike cutting taps, forming taps do not remove material to create threads. Instead, they work by deforming the material to form threads. Forming taps are commonly used with ductile materials, such as aluminum or brass, and are known for producing stronger threads with improved dimensional accuracy.