Pin Drum Coupling

Rokee® is a Pin Drum Coupling Supplier from China, customized pin drum coupling according to the drawings which provided by the customer, selling chinese national standard pin drum coupling, support export, due to excellent quality, complete technical services and superior cost performance, Rokee® industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

The pin and bush couplings accept parallel, angular and axial misalignment and can provide considerable torsional flexibility. The flexible pin gear coupling is designed with non-metallic flexible pin, two toothed semi-couplings and a toothed sleeve ring with an outer ring. It uses non-metallic flexible deformation to transfer torque and cushion shock and compensate angular displacement.

The flexible pin coupling is a basic transmission parts that has simple structure, needs no lubrication, and is easy to manufacture, install and disassemble the flexible pin. It uses two semi-couplings with flange holes and a non-metallic flexible pin for crane to transmit torque, suitable for low-to-medium speed and low-to-medium torque occasions.

The design of the elastic sleeve pin coupling is simple and clever in design and has wide applicability. It uses the pin with elastic sleeve to connect two semi-couplings with pin holes to realize torque transmission and larger angular compensation. At the same time, it has good shock absorption and buffering performance, which can be used in high-speed occasions without lubrication and requiring easy pin sleeve replacement.

-

LTZ/TLL Elastic Sleeve Pin Coupling

LTZ/TLL Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LT/TL Elastic Sleeve Pin Coupling

LT/TL Elastic Sleeve Pin Coupling is the basic form of this series of couplings. -

LXZ(HLL) Flexible Pin Coupling

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LX(HL) Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings. -

LZZ/ZLL Pin Gear Coupling

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LZD/ZLD Pin Gear Coupling

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end. -

LZ/ZL Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.

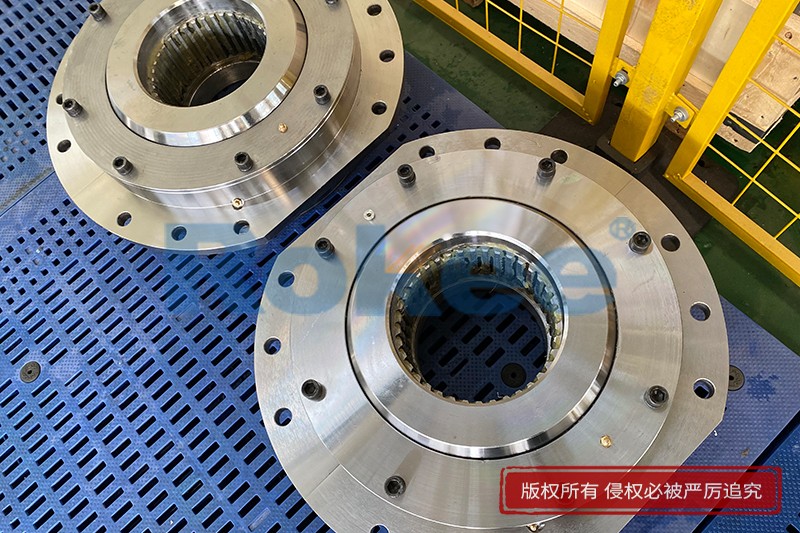

The drum coupling is the crane drum coupling. The internal sphere gear sleeve is assembled with the external drum perfectly. Relying on the specially designed key, the external sphere shaft sleeve forms the entirety with gear sleeve perfectly. It will promote the reliable connection of reducer shaft and drum and it is the most ideal product in the market home and abroad at present.

RWC series drum coupling is a type of high-performance drum coupling developed by us and mainly applied for port lifting and large mechanical lifting. In comparison with international DC series products, it has identical outline and connection size, but its interior design is more thorough and steady. The hook face of gear is optimized and the large pressure angle design is applied. A patented mechanism is used for the sealing. One-time filling of lubricating grease is basically free from maintenance, solving maintenance difficulty at heights. In addition, an electronic warning device is set. When the wear life reaches the safe position, the weak current connection will trigger the alarm immediately. It’s a good choice for you!

-

RWC Ball And Drum Gear Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life. -

WZL Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure. -

DC Drum Coupling

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load. -

WJ Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. -

WJA Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.

« Pin Drum Coupling » Post Date: 2023/10/24

URL: https://www.rokeecoupling.com/en/blog/pin-drum-coupling.html

- Precision servo diaphragm coupling

- Manufacturer Of Gear Coupling Processing

- Brake Elastic Column Pin Couplings

- Water Pump Diaphragm Coupling Price

- RODW Brake Wheel Drum Gear Coupling

- Guide Rail Diaphragm Coupling

- Professional Elastic Pin Couplings Wholesale

- Advantages Of Curved-tooth Gear Couplings

- Types Of Automated Diaphragm Couplings

- Metal Disc Coupling Specifications