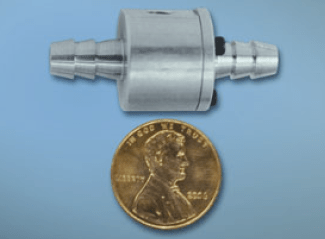

EXAIR’s Air Operated Conveyors, or Line Vacs™, provide an efficient method of converting ordinary pipe, hose, or tubes into powerful in-line conveyors. To accommodate the wide variety of unique problems, EXAIR has the ability to customize and tailor-make Line Vacs with different specifications. Certain processes may require customizations like unique sizes, shapes, and materials in order for the product to be a perfect fit for their system. EXAIR will work in collaboration with our customer to fabricate the best possible Line Vac solution for easy and efficient conveyance.

I worked with a customer to design a special Line Vac. They needed 3” ANSI 150# flanges on a 3” PVDF Line Vac. So, we had a special material with special ends to fit their specific needs. The PVDF with Hastelloy hardware was for chemical resistance, and the flanges would mount into their piping system. As with many of our Line Vacs, we can turn a normal piping system into a conveyance system for waste, parts, evacuation, or bulk materials. For this customer, they needed a backup system for a fume hood. With electrical vacuums and blowers, loss of power or motor failures can cause a momentary lapse in fume removal. Since the chemical material that was used in the hood was dangerous, they needed a reliable source to extract the fumes. The Line Vac does not have any moving parts or require electricity. Line Vacs only use compressed air or gas to make them operate. For this customer, they attached nitrogen to the special Line Vac to operate when there was a power failure to protect the workers in the area.

With the EXAIR design, we can alternate connection types. For example, we can add a threaded end to connect to pipes on one side while having a slip-on end for hose connection. In situations where the Line Vac requires a specific flange mounting option, EXAIR can accommodate. EXAIR stocks 316SS Sanitary Flange Line Vacs, but we have done ANSI or DIN flanges as well. For applications where stock aluminum, 303, or 316 stainless steel won’t work, alternate materials like PVDF, PVC, or PTFE can be utilized. Even in extreme environments, EXAIR can produce both heavy duty and high-temperature iterations to handle even the toughest materials or conditions. Other details, like particular hose sizes or pipe threading, can be specified to us.

Stock Line Vac models include standard, heavy duty, light duty, and sanitary flange. All versions can be customized to meet customers specific needs. All Line Vacs are CE-compliant and OSHA-safe. For help solving any specific conveyance problems that you may have, please contact an Application Engineer at EXAIR. We look forward to your challenge.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb