Recently I blogged about a refrigerant leak in my homes HVAC system. For that, I had to use a special leak detector which sniffed out gases within the air. Compressed air systems are not as complicated and a simple Ultrasonic Leak Detector can be utilized to find leaks that may be getting you down. Those compressed air leaks can cause inaudible pressure loss within a production line. This leads to equipment faulting out, maybe even compressors over working and an increase in energy demand. So how do you fight a foe that you cannot see, feel, or hear?

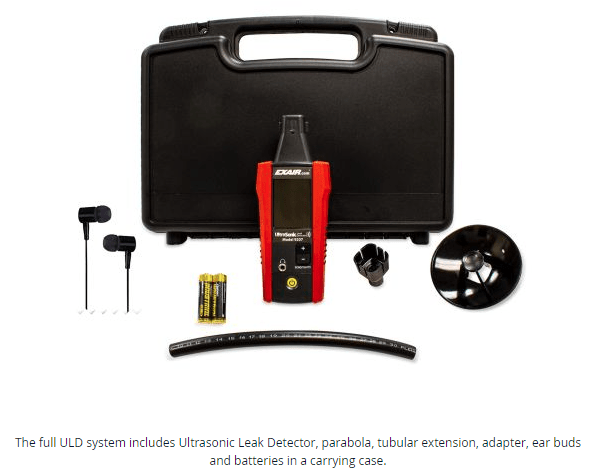

Equipping yourselves with the right tools is the ideal way, converting ultrasonic emissions into an audible level by the human ear and a visual representation as well can be done easily with the new EXAIR Ultrasonic Leak Detector. This detector was demoed by Tyler Daniel in a recent video and can be shipped same day on orders received by 2 PM ET that are shipping within the US. So why exactly do you need to worry about this?

Well, leaks can actually account for up to 30% of an industrial facilities compressed air capacity. If you have a 2,000 SCFM compressed air system, That could result in 2,000 * .30 = 600 SCFM of compressed air being wasted. 600 SCFM costs the average user $72.00 USD per 8 hour shift of operation. If you operate for 3 shifts per day and average 6,000 hours of operation per year, then that equates to $54,000 USD per year in savings if you just find and fix the 30 % of airflow that is leaking out.

If you want to discuss how to use the ULD or what a good approach is to how to break down and optimize a compressed air system, that is what our entire team of Application Engineers is for. Contact an Application Engineer today!

Brian Farno

Application Engineer

BrianFarno@EXAIR.com

@EXAIR_BF