I have been working with a customer from the grain milling industry. They take a grain like corn, and mill it to sizes that range from coarse product like grits to fine product like flour. The customer had a special application where steam was injected into a mixing screw process to add moisture to the grain. Steam can be expensive and dangerous to work with, due to the energy required to make, store, transport and use, along with the high temperatures and pressures involved.

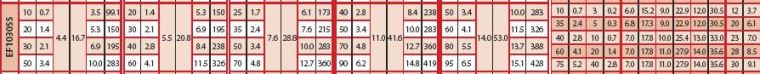

The customer was aware of our products from previous work we had done involving Super Air Knives. He approached me about the Atomizing Nozzles and whether they could be used to replace the steam injection system. We reviewed the process details such as target flow rate, the spray pattern desired, and the available distance from the target we had to work with. We determined that (3) of the EF1030SS – External Mix Flat Fan, each capable of delivering 14 Gallons Per Hour, were the solution. The nozzles would be placed equidistant along the mixing screw, to provide an even delivery of water.

To operate the nozzles, all that is needed is a supply of water, and 3.5-15.1 SCFM of compressed air at 10-95 PSIG. Varying the liquid and air pressure will change the flow rate and pattern size of the spray. Charts are published to help with the set-up and tuning of the nozzles to match the process needs.

The use of the Atomizing Nozzle allows for precise application of very fine droplets. For the External Mix type, droplets sizes of 39 to 57 micron are possible. Smallest droplet size is achieved by operating at higher air pressures and lower liquid pressures.

EXAIR also manufactures Internal Mix type nozzles and even a Siphon type, that can operate under siphon or gravity fed conditions (no liquid pump/pressure is required.) Nozzles are available with flow rates from 0.1 to 303 Gallons per Hour, in flow patterns such as Narrow Angle Round, Wide Angle Round, Flat Fan, and 360° Hollow Circular.

To discuss your application and how the EXAIR Atomizing Spray Nozzle can be a benefit at your facility, feel free to contact EXAIR and myself or one of our other Application Engineers can help you determine the best solution.

Brian Bergmann

Application Engineer

Send me an email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_BB